Directional drilling company SADB is combining the power of the Leica iCON gps 160 rover and BricsCAD software.

PARTNER FEATURE

SADB is a family-owned company that began life back in the 1960s as a tree-lopping and landscaping business before evolving in the 1990s into a horizontal directional drilling and civil construction company.

“The horizontal directional drilling is the really unique part of our business,” said Sam Taylor, SADB’s Business Services Lead. “Rather than ripping up the road to put pipe in the ground, we can just politely drill from one side of the road to the other, under the surface. We can even do it while people are still using the road above, under bodies of water and across mass highways, covering kilometres of piping underground.”

The avoidance of disruption to what’s happening on the surface is a major consideration, according to Sam. “If you’re looking at it from a holistic point of view, it is impactful on the environment than trenching, too — we’re not disturbing any of the nature up on the top level.”

Drilling down

Naturally, one of the prime considerations when drilling is to avoid any underground services such as gas and water pipes or electrical cables. And that’s where precision positioning comes in.

Since late last year, SADB has been using a suite of solutions supplied by C.R. Kennedy to improve the accuracy and efficiency of its operations — a Leica Geosystems iCON gps 160 GNSS smart antenna along with iCON site software for field pickup and set-out, and Bricsys BricsCAD software for design and analysis. Previously, SADB had to outsource to third party survey providers.

The iCON gps 160, which SADB uses as a rover (it can also be used as a base station or for machine guidance), is designed to provide versatility for the construction industry. It features a large colour display and a quick setup without the need for extra hardware, plus tilt compensation of up to 20 degrees (along with an optionally available IMU to further increase efficiency with tilt-compensation). Other features include SmartLink Fill, which bridges interruptions in the RTK connection signal for up to 10 minutes; an integrated global modem; IP66/IP67 protection; and seamless integration with other Leica iCON field solutions.

The iCON site software is designed with construction and civil engineering projects in mind, providing increased performance and productivity on-site through its smart digital workflows and easy-to-understand user interface, all of which act to improve quality and reduce errors. Cloud connectivity, through Leica ConX, enables quick and safe exchange of data, reports and design updates… not only between different locations but also between personnel and machine operators on the same site.

Sam explains how a typical job works with the iCON equipment. “First, the client will give us a design drawing and we’ll use that to search Before You Dig Australia [previously Dial Before You Dig] to find out which, if any, services are in the area where we’ll be working”.

“We’ll then do a site visit to accurately determine the exact location of services, positively identifying where needed. This will then dictate where the pits will end up being dug — the entry pit and exit pit; we drill from one to the other. So of course, the pits have to be in locations where there’s no power or gas.”

“We use the iCON gps 160 rover to mark up the alignment from one pit to the other and produce the drawings. Then the drilling occurs based on the alignment we’ve chosen.”

In the past without the rover, SADB would have had to arrange for a service locator to come out and mark up the alignment by painting the ground or grass. But after just days or weeks the grass would have grown or been cut, or the rain would have come and washed away the paint… so it’d have to be marked again. Sometimes it would need to be marked three or four times in the course of a project.

Or if the job had needed a surveyor, it might have meant waiting until a surveyor was available. “And of course, that tied up our resources, plus having to take the surveyor out to site and explain the job to them. It took up time on both our side and also for the surveyor,” said Sam.

But the iCON gps 160 is so easy to use and so efficient that SADB’s own in-house engineers can do the job themselves. “Now with the rover, we mark the locations and then we have them forever,” added Sam. “We don’t have to worry about sending someone out there again.”

“The rover is very easy to catch on to,” said SADB engineer, Immanuel Ibeanu. “If there is a cadastral drawing for the project, you just throw that onto it and see the overlay of the drawing. Then you set up the coordinates for that particular project, and more often than not the plan says what the coordinates are. Then once all of that is set up on the rover, it is just a matter of going to site, setting up your equipment, grabbing the rover and just measuring points as you go.”

“It is a really efficient set up and it’s easy to get what you need,” he added. “Depending on the size of the project, it will normally take me one to two hours to pick up all I need, then I’m back to the office and uploading the data onto BricsCAD.”

3D by design

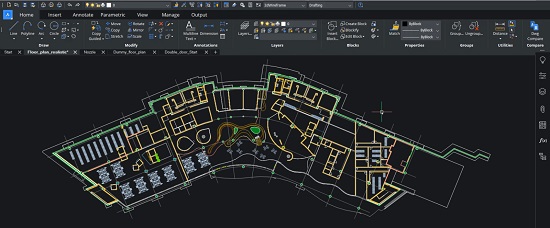

BricsCAD, developed by Bricsys (part of Hexagon), is a set of CAD and modelling tools made specifically for designers and engineers. Broadly speaking it features six functional tool sets: 2D drafting, 3D modelling, civil and surveying design tools, point cloud import and processing, 3D BIM tools, and 2D and 3D mechanical design.

BricsCAD enables users to add industry-specific toolsets using hundreds of third-party applications, while custom workflows can be built via LISP, .NET or BRX APIs. Menus and user interfaces can be customised, and you can even migrate legacy customisations from AutoCAD. It also enables the user to exchange design data freely across all project stakeholders using all major file formats.

Those comprehensive features and the ability to handle 3D has meant SADB’s experience with BricsCAD has been very positive.

“We had AutoCAD in the office, which can read two-dimensional drawings. But because the rovers produce 3D information, we needed software that could read 3D,” said SADB project manager, Alan Thong. “And BricsCAD is a system that is relatively cheaper than AutoCAD. So that’s why SADB is going down the path of making BricsCAD our go-to software.”

A helping hand

Like any new system, it takes time to get the hang of it. That’s why after-sales service and assistance is so vital, as time is money. And one of the great advantages of the iCON equipment is that remote assistance can be provided on the spot.

“As a beginner using the rover, I’ve gotten a lot of help from C.R. Kennedy by just connecting to them wherever I am on the job site, on the tablet, so they can see exactly what I’m seeing and go through it step by step on what I need help with,” said Immanuel. “The rover has a SIM card in it which it uses to connect to the Internet, so when we need help with it on site, whether it be on Kangaroo Island or wherever, we can call C.R. Kennedy and say, ‘Hey, can you please log into my device?’ and they can work to resolve the issue.”

Sam agrees, saying that SADB looked at three or four different suppliers and, after a detailed investigation, ended up going with C.R. Kennedy.

“C.R. Kennedy has been very helpful and co-operative and have gone out of their way to assist us in various ways,” he said. “We were up and running and doing in just weeks what would previously have taken months to complete.”