The Port of Newcastle has a port-side land area of 792 hectares and numerous berths. All images are courtesy of Port of Newcastle.

Port of Newcastle is the largest deepwater global gateway on Australia’s eastern coast and one of the country’s busiest ports, responsible for shifting more than 164 million tonnes of cargo worth roughly $26 billion each year.

Imports include alumina, cement, fertiliser, machinery, vehicles, fuels, wind turbines, grains and steel. Exports include aluminium, coal, machinery, grain, wheat and many others.

Keeping cargo trade moving safely and efficiently in and out of the Port is vital to its operations, and this is where hydrographic surveying plays an important role, providing Port of Newcastle with the right information to make informed decisions.

In charge of the hydrographic surveying is Hydrographic Survey Manager, Robert Kelly. We spoke with him to find out all about the Port’s survey operations.

POSITION: Can you give us an overview of Port of Newcastle and its operations?

ROBERT KELLY: Port of Newcastle (PON) entered into a 98-year lease with the NSW government in 2014. PON manages the 792 hectares of port-side land and the channel (including berths) and is equally owned by The Infrastructure Fund (an Australian superannuation fund managed by Macquarie Infrastructure and Real Assets) and China Merchant Ports. The Port handles around 4,400 shipping movements each year.

POSITION: How vital are surveying operations?

RK: For safety of navigation, it is critical for the Harbour Master and pilots to be aware of the available water depths within the channel and berths. The Port is at the mouth of the Hunter River, so there are suspended silts that deposit within the channel. This is due to the water slowing in velocity due to the deeper water in the Port channel compared to that of the upstream river system.

POSITION: How frequently do you conduct surveying operations?

RK: We have a survey schedule that is determined by risk assessment. The historic rates of siltation in particular areas and the use of different berths determine the frequency of surveys. We would generally be on the water two to three days per week, with processing of data on the other days. Beyond the survey schedule, the survey team conducts progress surveys for Port of Newcastle’s dredger, the David Allan. The David Allan operates seven days per week, so making up-to-date survey information available improves the dredger’s productivity.

POSITION: What sort of survey equipment do you use?

RK: Our survey platform is an 11-metre catamaran with twin 250hp motors. From this vessel, the JT Gowlland, we deploy a R2Sonic 2024 multibeam echosounder (MBE). The MBE is supported by an Applanix Oceanmaster POS MV inertial motion unit and navigation system.

Members of the Port’s survey team aboard the survey catamaran, JT Gowlland.

POSITION: How many people are involved in the effort?

RK: We have a team of three surveyors, all of whom are also qualified coxswains. To conduct survey activities, we have two people on the vessel, one as the surveyor and the other as the coxswain/vessel master. The roles will alternate over the course of the day or week. Processing of the collected data is completed in the following days to generate charts for navigation.

The survey schedule provides for a base load of survey operations and frequently triggers a dredging response if silt accumulations are identified. The dredging operation in a particular area will then (in turn) require progress surveys to ensure required depths are achieved. During a flood event an intensive survey program is mobilised to provide up-to-date survey data to the Harbour Master and the dredger. Fortunately, we have a lot of experience with flood events within the harbour and can prioritise known areas of siltation.

POSITION: Are there any potential hazards or safety concerns?

RK: On the water it is the coxswain’s responsibility to navigate the survey vessel safely. As a city port, Port of Newcastle is shared with a reasonable number of commercial and recreational users each day, from fishing vessels to kayakers, so the coxswain must always be aware of other Port users. There is also the risk, particularly during flood events, of the vessel impacting floating debris. Offshore there is the risk of capsize with swell events, so it is important to be aware of the weather forecasts and warnings. We have rigorous safety procedures in place, and it is factored into the way we approach all our work, particularly on the water during surveying operations.

POSITION: Once you’ve surveyed the Port, what are the next steps?

RK: During routine surveys, from the 3D model, a fair sheet chart is created — both electronic and paper — for inspection and promulgation by the Harbour Master. Essentially the Port channel is only as deep as the shallowest point, so this becomes the governing location for safety of navigation.

The 3D model is transferred to the David Allan and the Dredge Masters are tasked with removing the excess silt that has been identified during the survey. The QPS software Qinsy interfaces with the dredge control systems and updates the on-board 3D model as dredging is conducted. In this way, the Dredge Masters can monitor progress and target remaining areas. Once the Dredge Masters are satisfied that enough material has been removed, the survey team returns to conduct a progress survey and a new chart is created.

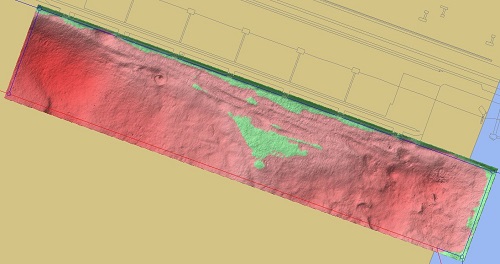

Plan view showing the siltation to be dredged within a shipping berth box.

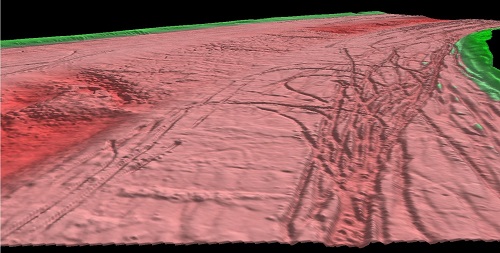

A 3D view with bathymetry, showing dredge progress and extents of the shipping channel.

POSITION: How long have you been involved surveying?

RK: Originally from Newcastle, I worked with a local surveying consultancy during university and a surveying consultancy in Dubbo before heading overseas and working in construction surveying and management in London, St Lucia, the Bahamas and Jamaica. Following my return to Australia in 2007, I was a NSW cadastral surveyor in Tweed Heads. I have been on the water at Newcastle since 2011, initially with the Newcastle Port Corporation and then moving across to Port of Newcastle during the 2014 lease transaction.

POSITION: Has much changed during your time in the industry?

RK: I entered the industry several years after multibeam technology had been firmly established. Since 2011 I have seen many new features on multibeam echosounders, such as sector rotation, automatic gates and range settings. From the motion units, the addition of post processing has allowed surveys to be completed when GPS solutions drop out in real time, which previously meant the job would have had to be abandoned.

The technology changes that have occurred in the last decade have allowed the surveyor to spend less time on the processing of data and more time concentrating on how to use the data. I see this continuing as the hardware vendors automate many of the features, allowing the surveyor to gather cleaner data that is processed quicker and can be shared more easily.

POSITION: Does Australia have enough hydrographic surveyors?

RK: Personally, I think that it is encouraging that a long-term commitment is being made to the HIPP scheme. This will give industry the confidence to invest in training of staff and for the creation of domestic education programs. Whilst I always see hydrographic surveying as an attractive option to other experienced spatial professionals, I think it is beneficial that a school leaver or surveying graduate can have the opportunity to have an entire career in hydrographic surveying.

This article was first published in issue 115 of Position magazine.

Stay up to date by getting stories like this delivered to your inbox.

Sign up to receive our free weekly Spatial Source newsletter.