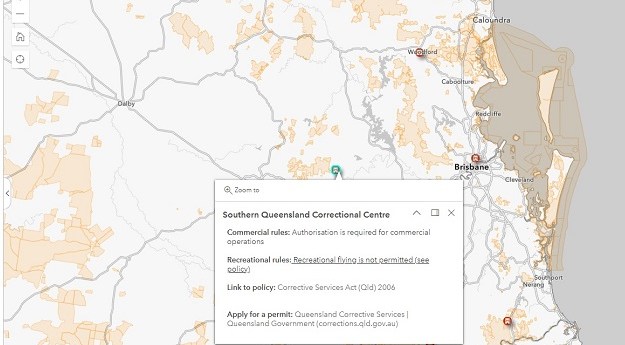

A screenshot from the interface of a digital twin excavator project under development at UNSW. Image supplied.

Digital twin technology has the potential to transform the construction industry through its automation potential and accessibility, according to Dr. Samad Sepasgozar from UNSW Built Environment.

Dr. Sepasgozar holds that safety and productivity are set to be transformed by the rapidly maturing technology, which may also particularly benefit smaller entities in the construction industry.

The idea is that for every physical item in the world, there could be a virtual replica with which it connects, housed in the cloud, collecting vital data on the physical item’s performance in real time, he said.

“Industry players might confuse this with Building Information Modelling. But unlike this previous technology, the digital twin also enables users to control equipment,” he said.

“So, it enables job-site tasks to be performed remotely, which is useful for working through disruptions like Covid-19.”

Uptake of digital twins is accelerating rapidly in Australia, particularly in NSW, with the launch of the Western Sydney 4D digital twin and a newly-announced consortium.

Dr. Sepasgozar is developing a digital twin of an excavator at the UNSW school of Built Environment, which enables diagnostics and detailed analytics of the machine’s performance.

He says that ease of use and the potential low price points should see the technology proliferate as learning resources, and ultimately a fundamental tool for construction and adjacent industries for interacting with all stakeholders, including community consultation processes.

“Construction activities – whether it be a tunnelling project or light rail project – can have many impacts on neighbours, and [the] city from [an] emissions footprint [perspective], using the city resources, [affecting] safety and … disrupting the environment. This can be communicated accurately in real time with all citizens, construction companies and other stakeholders at the city level,” he said.

“We already have a lot of different types of sensors, drones, and other tools which will contribute to developing an entire construction digital twin. Everyone can participate in the data generation, and of course, the sharing platform will be [richer], and that can be more useful to the construction companies and the community as a whole in terms of sharing data,” he said.

“Most previous technologies, like Building Information Modelling (BIM), is implemented by bigger guys in the industry. But [here] we are talking about smaller stakeholders, people on the ground level, family businesses, the subcontractors such as excavation contractors.”

Stay up to date by getting stories like this delivered to your mailbox.

Sign up to receive our free weekly Spatial Source newsletter.