How Revolver Resources made its Dianne copper mine project more efficient with Mangoesmapping’s mapping and surveying services.

PARTNER FEATURE

Pat Williams, Managing Director of Revolver Resources, an ASX-listed public company specialising in mineral exploration, is passionate about demonstrating that mining can be done not only commercially, but also ethically and responsibly.

“We work to leave projects in a better condition than when we found them, and we listen to everyone with a stake in the projects,” he says.

Revolver Resources is currently focused on the Dianne Copper mine project, located about 260 kilometres northwest of Cairns. The mine was operational in the 1970s and 1980s, and Williams is on a mission to make it profitable again. “My stakeholders keep me motivated to deliver the best possible results in an ethical, timely and cost-effective manner,” he says.

Williams spends much of his time working to deliver results for his customers. For instance, while he had access to mapping and surveying services, he found that the remoteness and extreme environmental conditions at the mine made it challenging to achieve deliverables on the timescale required; that is, weeks.

“We found ourselves in unfamiliar waters with surveying and mapping; we were presented with project timelines of months from different providers when what we needed was to make decisions in weeks, not months,” he says.

“We’re recommencing the operations at the mine, and we don’t want hassles or delays if we get the wrong data or if the data doesn’t make sense. We’re working on a timeline to get information to assemble environmental amendment submissions, plans and designs on site.”

Williams discovered that engaging Mangoesmapping meant the project could recommence operations and get a return on investment faster, seeing final results in just weeks. He also enjoyed the personalised approach of Mangoesmapping. “Engaging Mangoesmapping services allowed us to keep going on a very tight timeline. They went the extra mile to suit our needs”, he says. “I was resigned to get answers in months until my project manager heard about Mangoesmapping — I see now, there’s a better way to do it.”

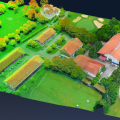

Mangoesmapping integrated four survey techniques for the project — control survey, ground survey, aerial survey and bathymetric survey. The company collected raw (static) data and employed RTK and PPK bases and rovers to deliver a 3D site model with sub-50mm horizontal and vertical positioning uncertainty.

Mangoesmapping gave Williams the information he needed, when he needed it and in the way that made the most sense to him. “Alistair and his team went out of their way to explain the technology and how it worked”.

“I know that the 3D mapping tells me almost, if not everything, that I need to know about our assets,” Williams added.

It was also essential to follow Queensland’s statutory regulations, with Williams expecting all external providers to follow procedures as per the mine’s health and safety policies. “The people who came to the mine site were implementing those procedures,” he says. “Mangoesmapping practice what they preach.”

Williams also valued Mangoesmapping’s transparency and accountability. “There were some risks with the terrain, even with the vessel doing the bathymetry. Alistair foreshadowed those risks, which were overcome, and we got good quality data over the whole project area.”

For Williams, Mangoesmapping’s end-to-end approach set it apart from any other provider he’s used. “I trust Mangoesmapping to deliver the surveying and mapping information I need, when and how I need it,” he says. “I’m confident I’m seeing the results to build my business plan and recommence the Dianne mine operations. I particularly commend Mangoesmapping’s passion for the geospatial space. The last thing I need as a business owner is to have people doing work they don’t want to do.”

“I’ve employed a lot of consultants in my working life, and Mangoesmapping has shown us that they are meticulous, accurate, fast and cost-effective. It is rare when service providers tick all these boxes.”

Full insights into the Dianne copper mine survey can be found in the case study video.

For more information, contact Mangoesmapping.com.au.